1. Mould design

A high quality mould start from a intelligent design. With rich experience of mould manufacturing and injection moulding, SBT’s skilled mould engineers can supply you DFM (Design for Manufacturing) moldflow, 2D mould layout and 3D mould drawing.

The core design and information would be displayed and discussed at the phase of DFM, which including:

Mould number, plastic type & shrinkage, cavity number, part layout, part line, runner design, gating way, ejection method, cooling layout and venting etc.

The photos of design and analysis:

2. Mould making

In SBT, 70% mould designed and used by ourselves in order to service our customers of EMS; while 30% export to foreign all over the world. Our capability:

We can supply different mould type, such as multi-cavity mould, multi-sliders mould, unscrew mould, insert mould and over mould. And 90% mould trial could be finished in-house. Furthermore, our precision machine of high speed CNC, Slow-WEDM, Mirror EDM, CNC-lathe could make sure the machined tolerance +-0.005mm. Some other skills are also important such as: Parallel and Concentric to make sure assembly and moving well, Mirror Polishing in a small inner diameter etc.

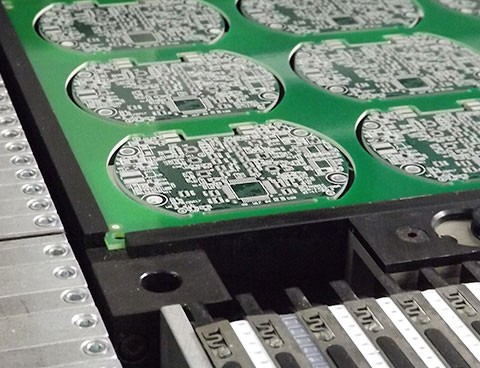

Equipment photos:

3. Plastic Moulding

Custom plastic moulding services:

A. No quantity restriction. Sample order is acceptable.

B. Capability: 60--1800 Ton.

C. Professional material selection. Many types material could be chosen, including: ABS, PC, PC+ABS, FR-ABS, PMMA, HIPS, PP, PE(HDPE, MDPE, LDPE) etc.

D. Free sample test. In SBT, most of the sample test is free and fast.

E. Spot check and painting or Ultrasonic welding etc...

Product photos: